Product and Service

Product and Service  Wellhead Safety Equipment

Wellhead Safety Equipment  Annular BOP

Annular BOP

GE Petroleum(Beijing) offers a wide range of annular BOP for onshore and offshore drilling operation Annular blowout preventer is designed for safe well pressure control during drilling and work over operations of oil and gas wells and submitted to erosion and corrosion due to solid and chemical particles contained in the drilling fluids flowing through the bore.

Manufacturing standard:

(1) Annular BOP, Rams BOP and Packers blocks: API Spec.16 A/ ISO 13533 & NACE MR-0175/ISO15156

(2) Flanged connections: API Spec 6 A /ISO10423 &NACE MR-0175 /ISO15156

(3) Ring Gaskets, Stud Bolts and Nuts: API Spec. 6A/ISO10423 & NACE MR-0175/ISO 15156.

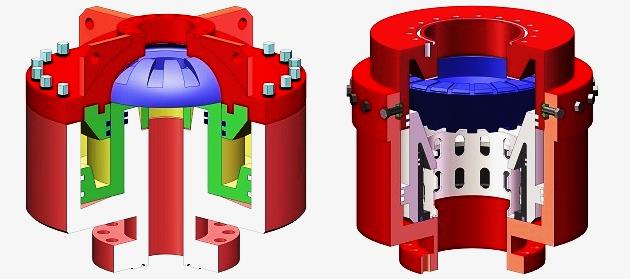

SB MODEL ANNULAR BOP SW MODEL ANNULAR BOP

Size: 7 1/16" -13 5/8" Size: 11" -13 5/8"

Pressure: 3000PSI - 5000PSI Pressure: 3000PSI - 10000PSI

FEATURES:

1. Strong simple construction and space saving design with only five major components.

2. Simple hydraulic system with only two hydraulic connections required.

3. Wear ring on moving parts to prolong the life of the preventers .

4. Easy servicing on field.

5. Low operating pressure.

6. Rugged reliable sealing elements.

7. Steel segments reinforce sealing element.

8. Long stripping life.

SB MODEL ANNULAR BOP

Size: 7 1/16" -13 5/8" Size(MSP): 21 1/4" Size(MSP): 29 1/2"

Pressure: 3000PSI-5000PSI Pressure : 2000PSI Pressure :500PSI

FEATURES:

1) Seal element molded with two different styles of inserts to reduce closing volume and increase closing cycles.

2) Replacement wear place that eliminates metal contact between the seal element inserts and the BOP head.

3) A piston design that provides complete balance more reliable operation and ease of assembly.

4) A latched head for fast, easy access to the seal element and wear seals.

5) An opening chamber head hat prevents debris from falling into the chambers when replacing the seal element.

6) Inner sleeve is bolted to the body that eliminates the difficulties in repair, and it is field replaceable